Get in touch

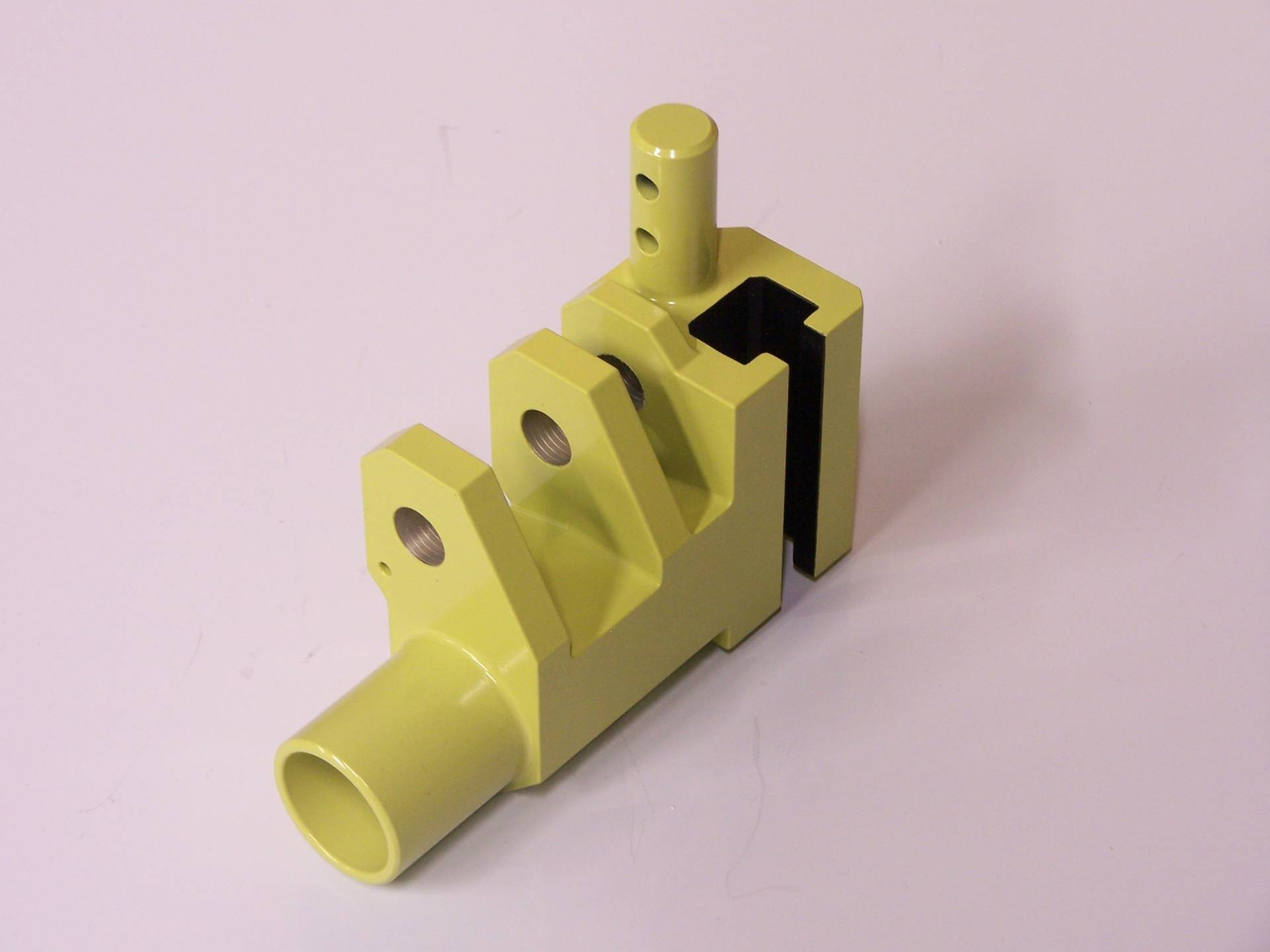

Advanced CNC Metal Machining for the Highest Quality Parts

Foresight Technologies was founded and staffed by experienced people from leading aerospace manufacturers who understood the importance of quality parts, a legacy that continues today. We have built manufacturing processes to deliver medium and highly complex parts at the lowest cost. We operate over 60+ CNC machine tools and continue growing our toolset to meet our customers’ capacity needs.

As CNC technology leaders, we strive to deliver a quality and cost advantage. We achieve this with our state-of-the-art flexible manufacturing systems (FMS), HMCs, 5-axis, mill turns, and multi-pallet vertical machining centers. Our continuous improvement efforts separate us from the pack.

We deliver significant advantages for you, including the latest CNC programming techniques, full ball-lock quick setup systems, vacuum hold-down systems, elimination of 90% of all setup requirements, automated coordinate measuring machines for inspection, and new methods for scheduling products throughout the facility.