Get in touch

Electroless Deposition for Advanced Packaging & Plating Applications

The semiconductor industry’s standardization of copper interconnect technology continues to represent significant investments in plating technology. Our electroless deposition chemical delivery systems are the industry’s leading solution to support this growing market.

Foresight’s wet chemical delivery product line is a turnkey solution for advanced plating and 3D packaging. Our systems connect and interface directly with advanced wafer plating tools and the fab’s bulk chemical delivery system. We have delivered thousands of systems that are installed in semiconductor fabs around the world.

Foresight owns the design and intellectual property, performs field upgrades, addresses obsolescence, maintains configuration control, and delivers production systems with our in-house engineers. These product lines are sold by leading OEMs or to fabs directly.

How CuSuite Wet Chemical Delivery Systems Ensure Consistent Electroless Deposition

Our CuSuite systems offer a complete multi-process tool delivery system controlled via a built-in central monitoring unit that automatically responds to the needs of up to four process tools. The systems’ industry-leading uptime of over 99% allows engineers to concentrate on plating wafers, not solution delivery.

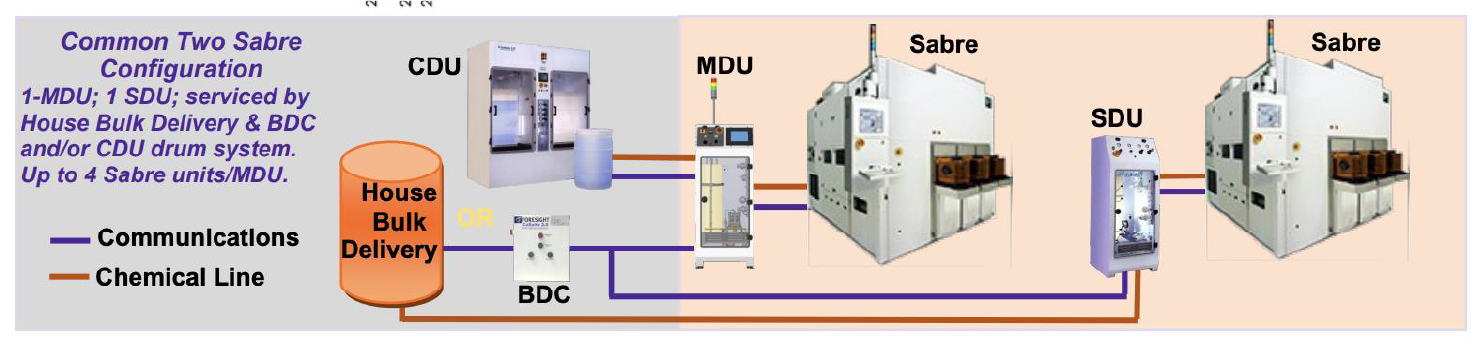

The master delivery unit (MDU) is central to system performance, as it enables integration into a single, centrally monitored control point and serves as the delivery point for the process tool. The MDU controls the functions of up to three satellite delivery units (SDUs) and the functions of the two 200L drum chemical delivery units (CDUs). The MDU uses a color touch screen to display the operations and status of the entire system graphically. Typically, the MDU is installed near the plating tools for convenient operator access and auto-configures to all CuSuite systems.

As a chemical delivery tool, the MDU provides a constant flow of plating solution at a constant pressure through its onboard pressure vessel. When the MDU is networked to the CDU, the pressure vessel is automatically filled from the CDU, allowing the MDU to provide a smooth, even flow of plating solution to the process tool when required. A 4.5-gallon pressure vessel offers additional capacity to the CDU in the unlikely event that the plating solution is unavailable. The small size of the MDU allows for installation close to the plating tool while occupying as little floor space as possible.

The MDU has extensive safety features, including automatic sensing for warning and shutdown. It is SEMI S2-0200 and S8 compliant and designed to meet the National Electric Code, National Fire Protection Association, and CE compliance.