Get in touch

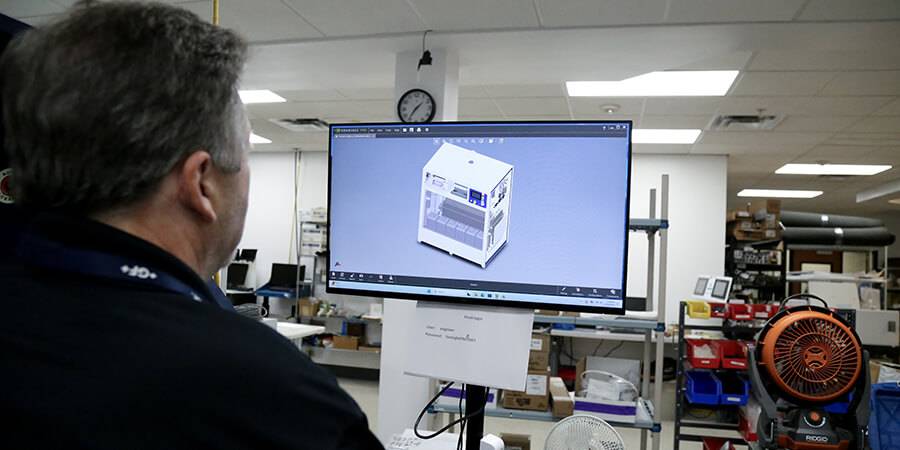

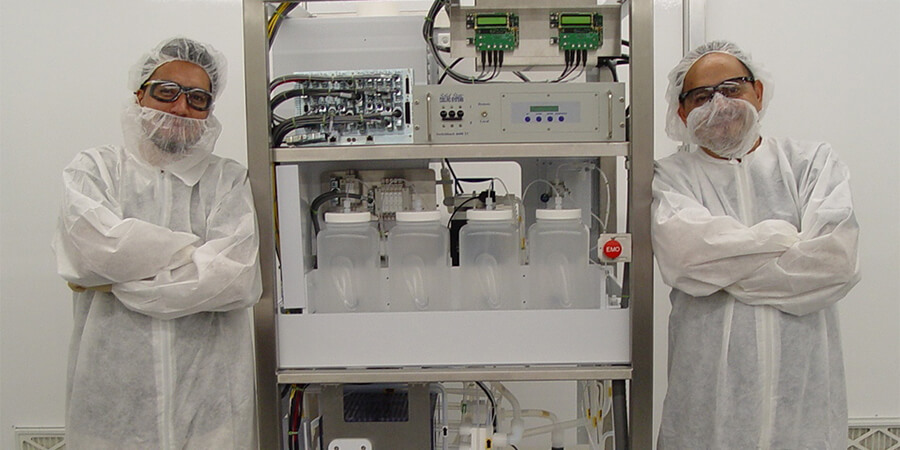

We Partner with You for Your High-Purity Facility Building and Equipment Needs

Foresight On-Site is not just another subcontractor; we are your partner. We bring unique value as specialists focused exclusively on chemical and high-purity DI infrastructure. We only take on jobs where we can provide high value to our customers. As a licensed and bonded C4 (pipefitting) subcontractor, we are the professional partner you need.

Our value-add for our customers is based on our unique, best-in-class offerings.